Infrastructure

- Research & Development

- Manufacturing

- Contract Manufacturing

- Sustainability

Excel Industries’ ‘culture of innovation’ thrives on the strong foundation of in-house research and development initiatives. Our state of the art R&D department is committed not only to leveraging the technical expertise acquired through years of experience but also to actively incorporating cutting-edge technologies. This proactive approach aims to address the continually changing business dynamics within the chemical industry, ensuring that we meet critical customer needs.

Excel Industries’ ‘culture of innovation’ thrives on the strong foundation of in-house research and development initiatives. Our state of the art R&D department is committed not only to leveraging the technical expertise acquired through years of experience but also to actively incorporating cutting-edge technologies. This proactive approach aims to address the continually changing business dynamics within the chemical industry, ensuring that we meet critical customer needs.

R&D infrastructures

- State of the art centre’s based at Mumbai and manufacturing sites at Roha & Lote

- 30 + proficient scientific staff

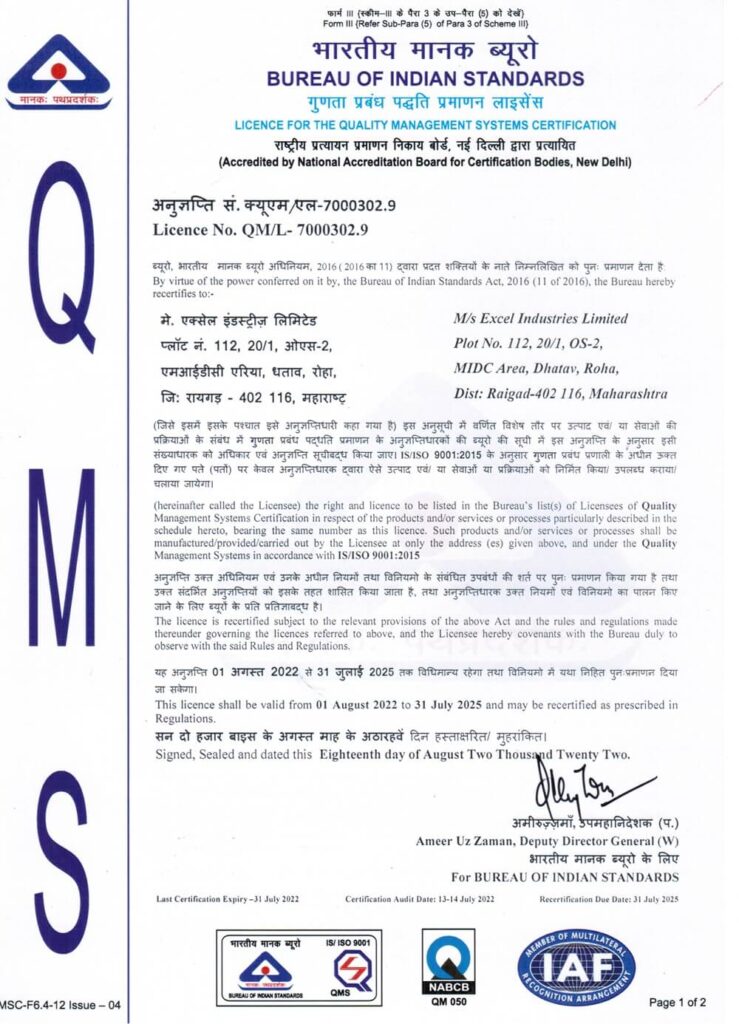

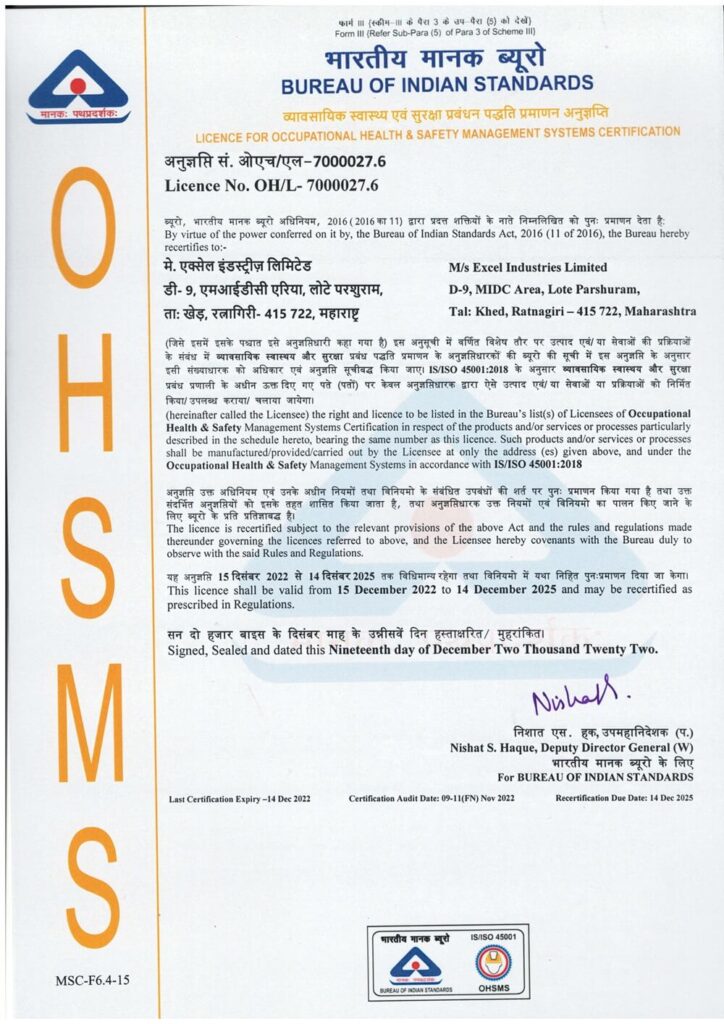

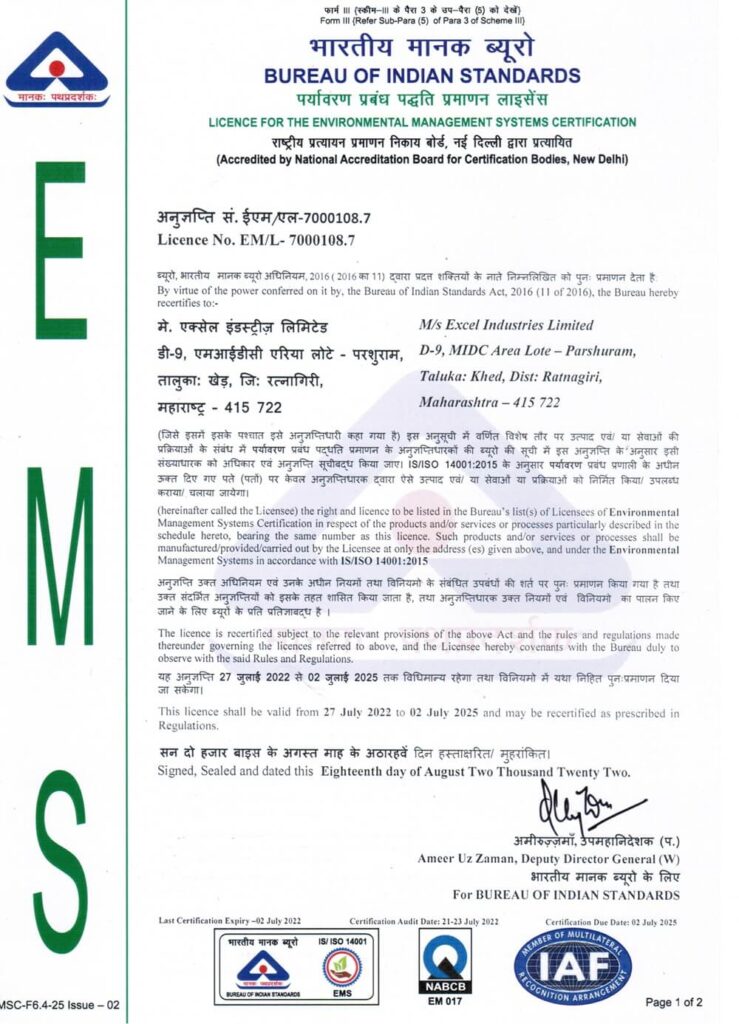

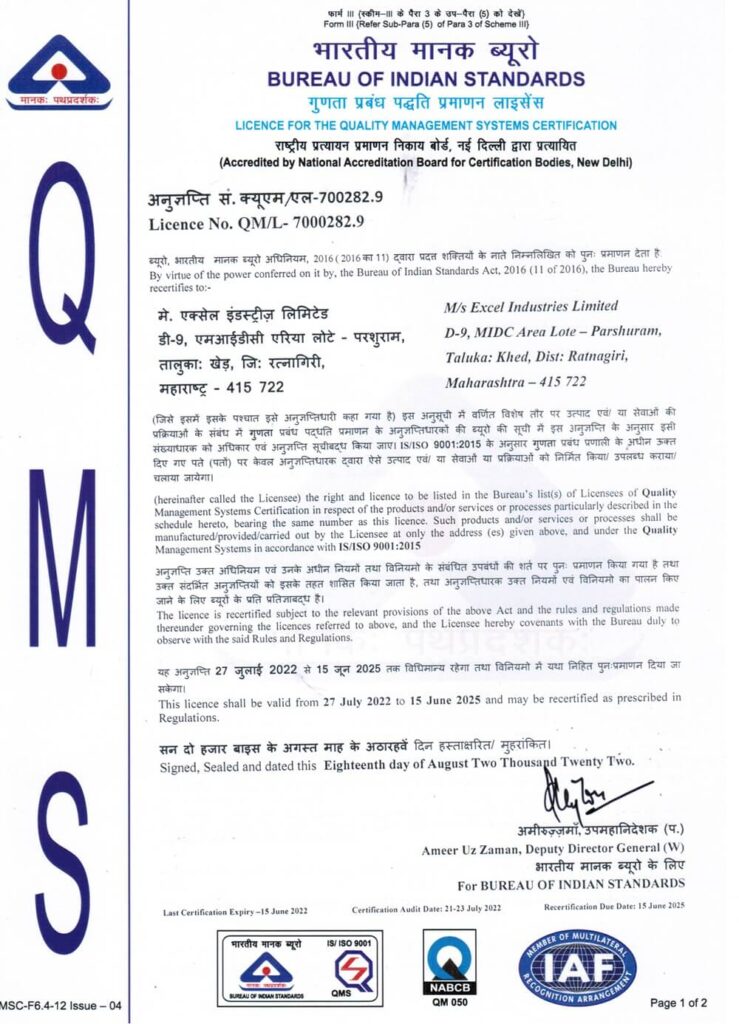

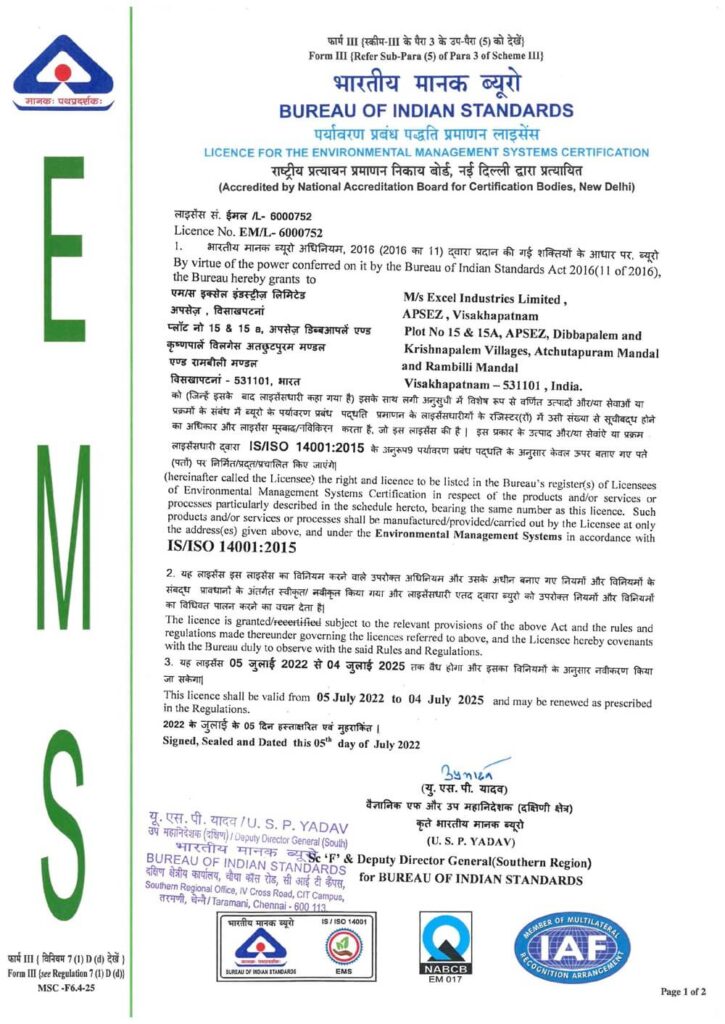

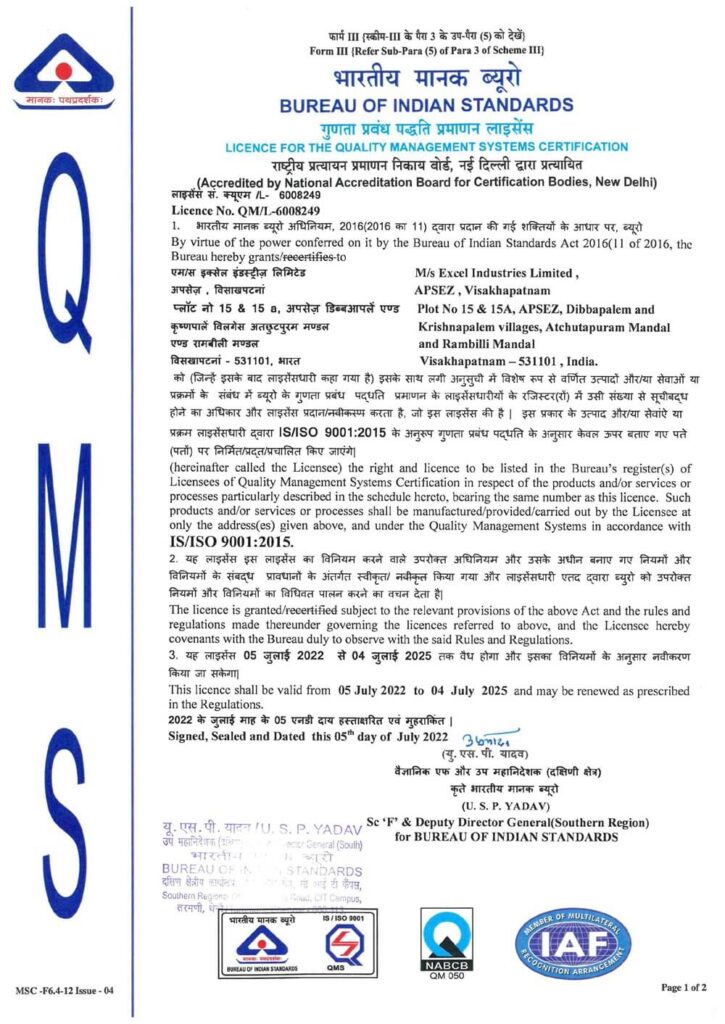

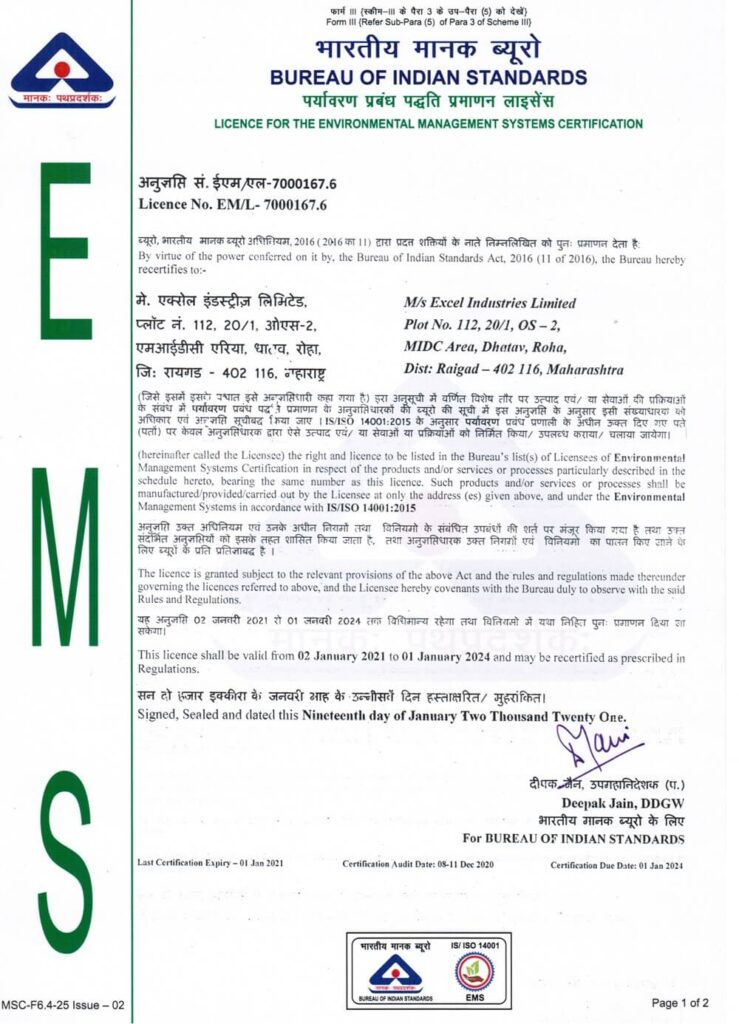

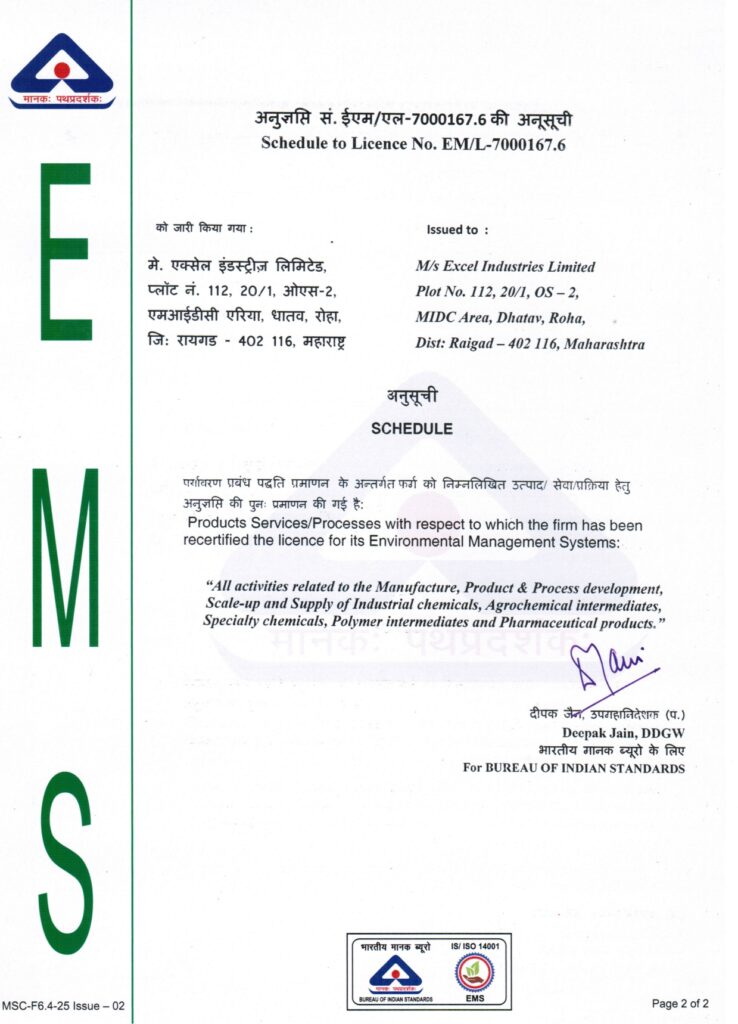

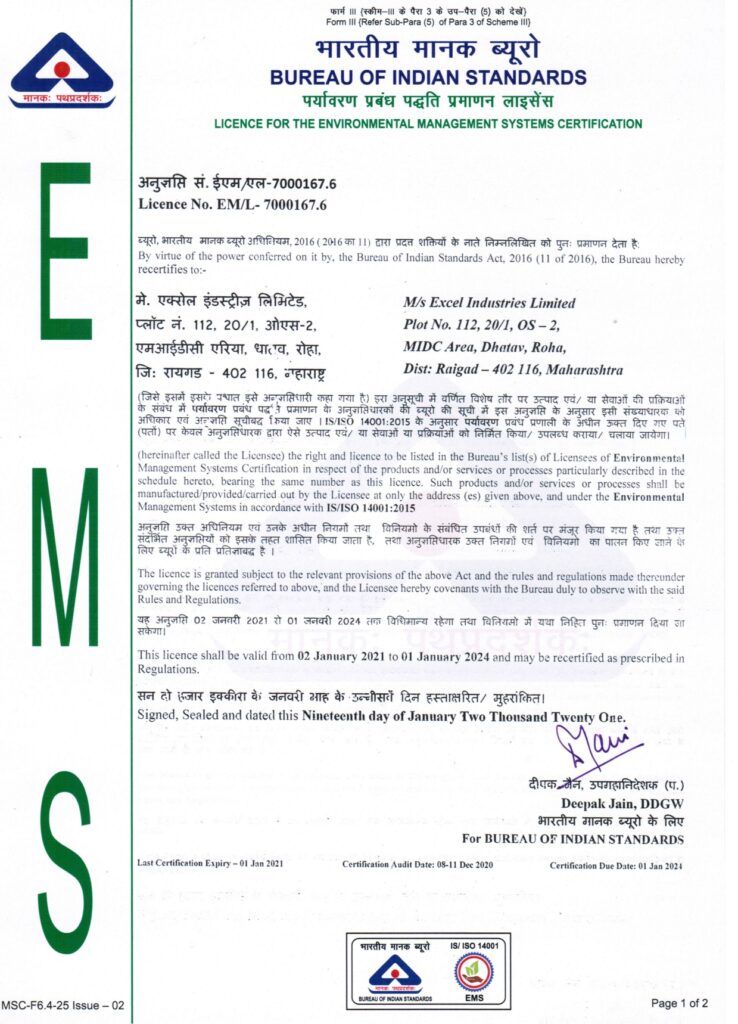

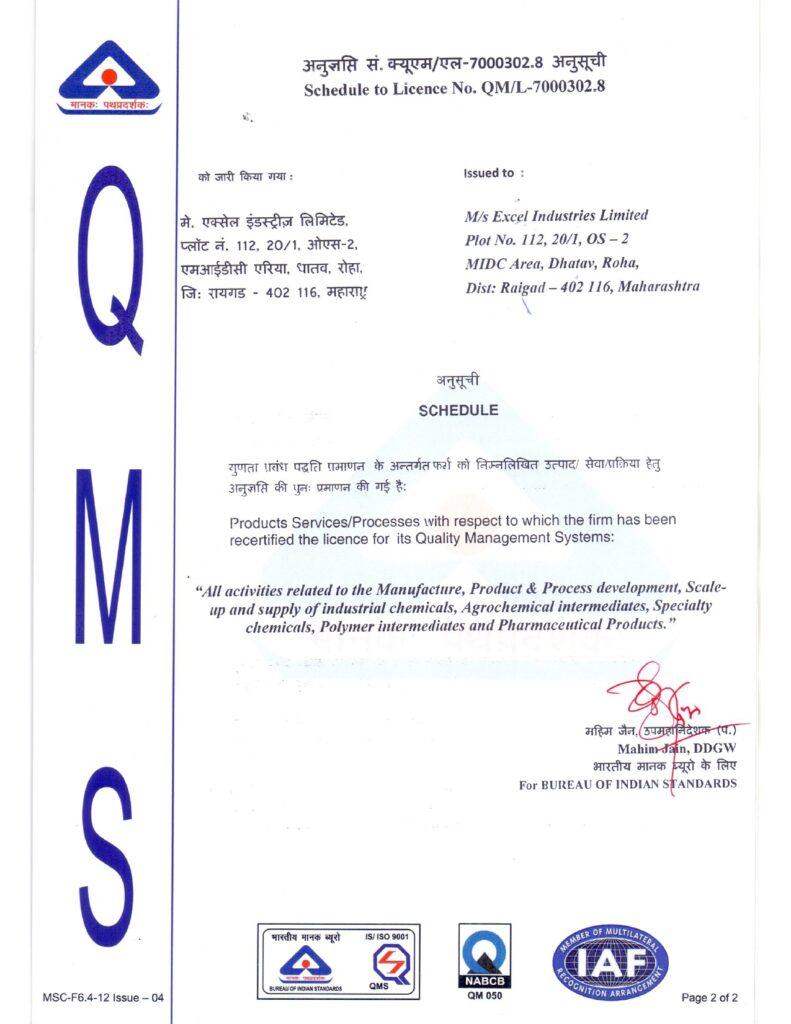

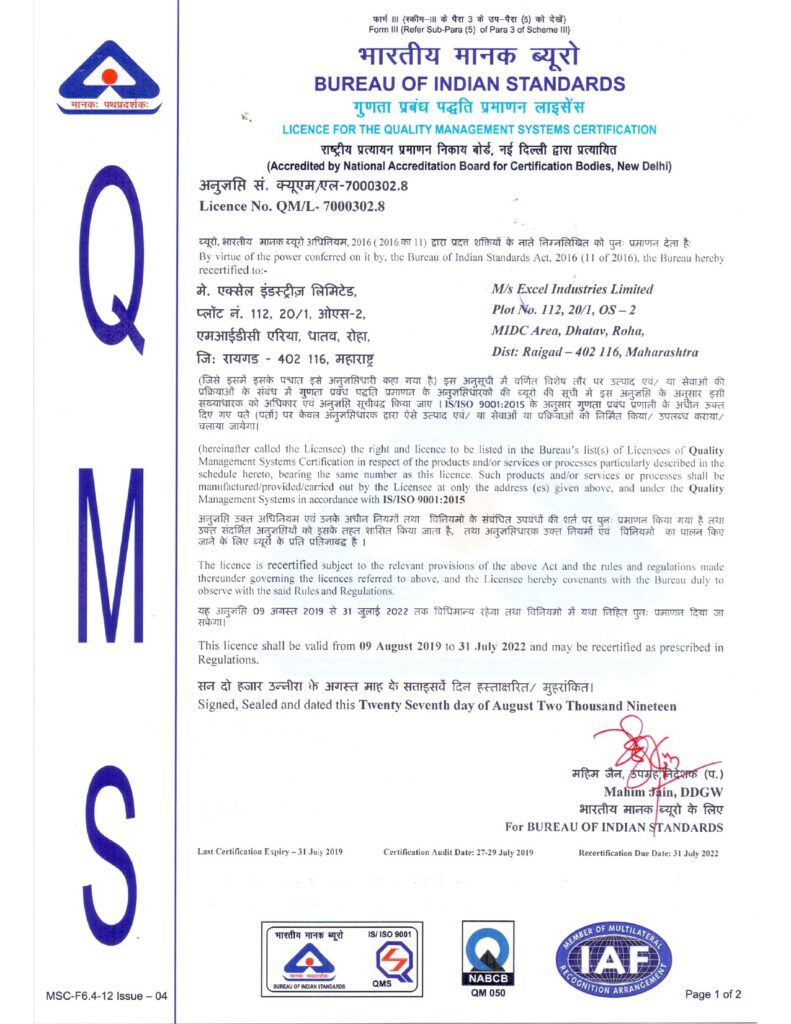

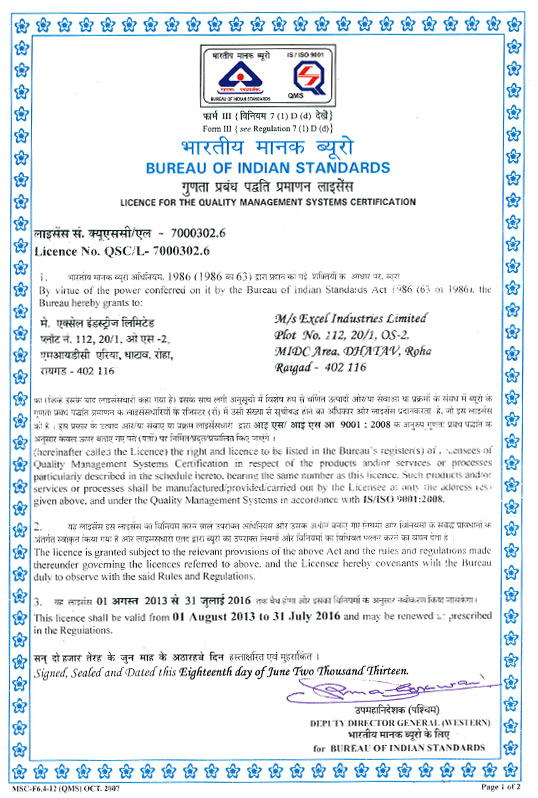

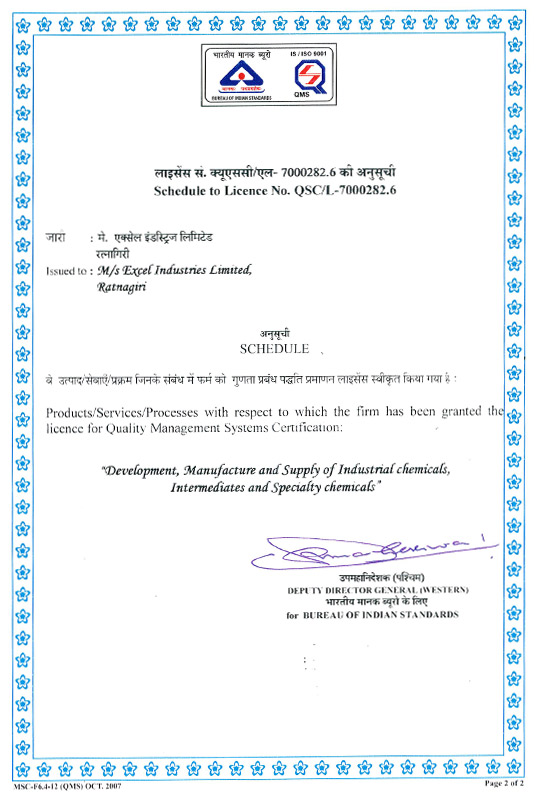

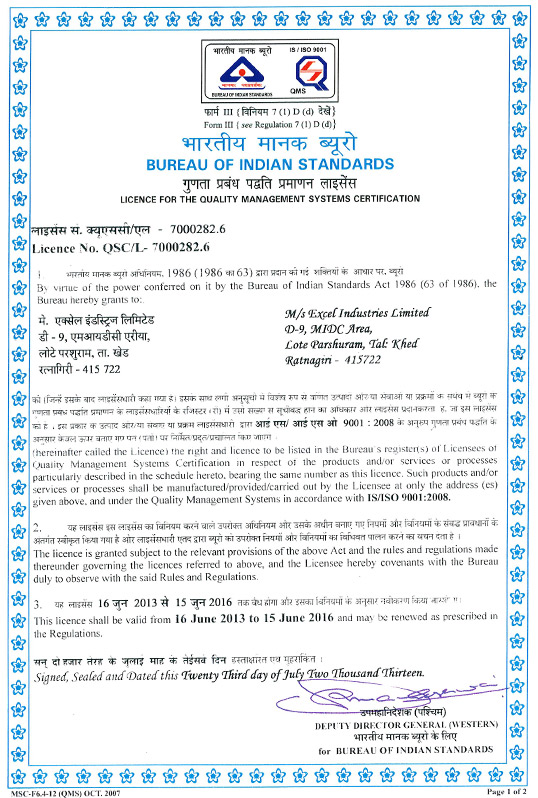

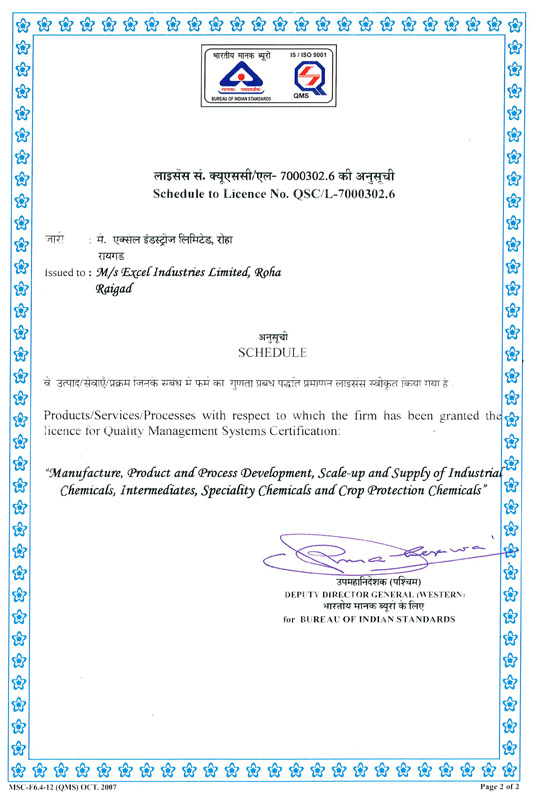

- DSIR approved facilities and ISO accreditations for QMS (9001) & EMS (14001)

- Well-equipped synthesis and analytical laboratories

- Infrastructure to perform low and elevated temperature reactions

- Autoclaves designed for vapor phase and hydrogenation (SS,R hastelloy and GLR)

- Expertise in handling of hazardous chemistries

Pilot infrastructures

- Multipurpose kilo & semi-commercial pilot plant set up for scale up studies

- Facilities managed by a team of qualified engineers

- Equipped with GLR, SSR, with capacity ranging from 20 L to 5 KL

- Pressure reactors SSR 500 L & 75 L HC 276

- Downstream operations – distillation, crystallization, filtration, drying etc

Reaction Capabilities:

Laboratory Scale

- Grignard reaction

- Balz-Schiemann

- Halex

- Hydrogenation

- Nitration

- Ammoxidation

- Bromination

- Cyanation

- Fluorination

Plant Scale

- Ammonolysis

- Chlorination

- Diazotization

- Esterification/Transesterification

- Mannich reaction

- Reductive amination

- Duff reaction

- Oxidation & reduction

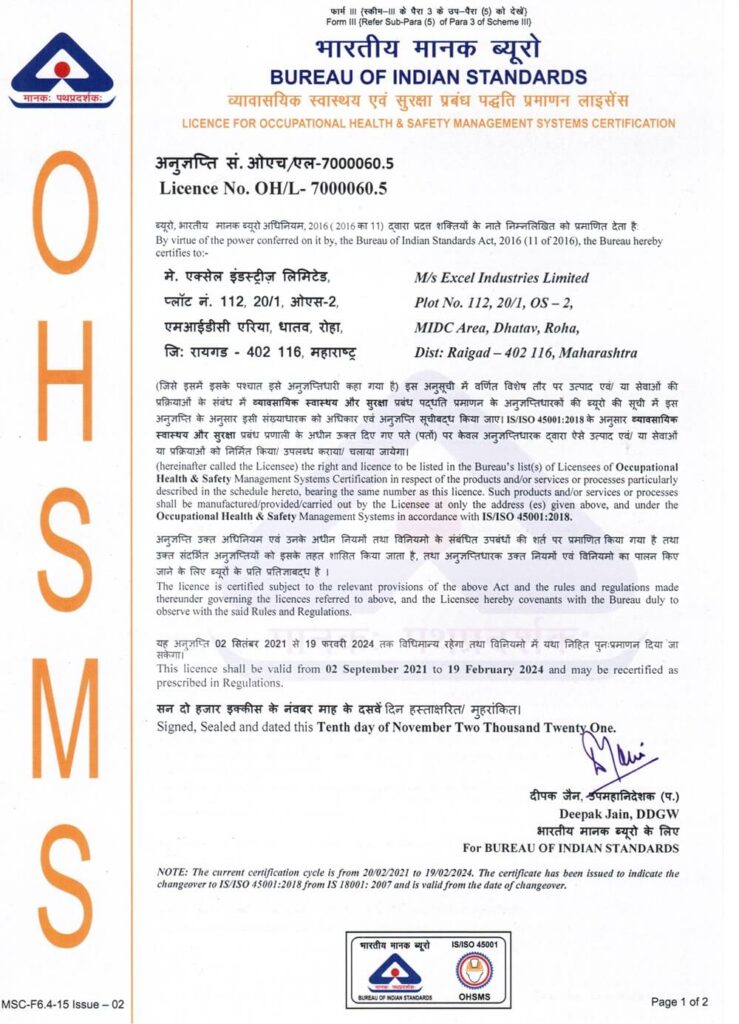

Roha

One of Excel’s first large scale facilities, our Roha site is situated 150 kms by road from Mumbai, Maharashtra. The site is fully certified for quality and EHS and is an important member of the local community. The Roha site is our hub for the production of a number of key phosphorus based products and it handles one of the highest quantities of yellow phosphorus in India. We manufacture a wide range of chemical inputs at Roha along with key polymer additives and specialty chemicals. Roha is also the location of our dedicated GMP plant for making Veterinary APIs. Excel Veterinary division manufactures a range of key veterinary inputs and APIs at the plant. The plant also integrates dedicated storage and stability analysis setup to ensure the highest quality product.

Lote

Set up in 1983, our Lote Parashuram facility is situated 250 kms from Mumbai city. It is part of a major chemicals manufacturing hub and benefits from extensive transport and power infrastructure in its vicinity. The Lote Parashuram site manufactures a wide range of specialty and performance chemicals. We are a leading producer of Organophosphonates which are used as chelating agents in a wide range of applications including water treatment, soaps and detergents, textile auxiliaries and cleaners. The Lote site also features a dedicated and self contained cGMP compliant pharmaceutical plant for dedicated production of pharmaceutical APIs and advanced intermediates. The plant integrates a dedicated research setup for developing pharmaceutical processes in partnership with clients as well as isolated storage facilities and stability study setup.

Vizag

The APSEZ Atchutapuram plant started in 2019, the facility is situated 60 kms from Visakhapatnam, Andhra Pradesh. It is part of an Agro intermediates and speciality chemicals manufacturing unit. The Special Economic Zone (SEZ) unit is especially the exporting unit.

To handle, grow and gain the leadership position in the competitive world is a huge opportunity to recognize and take advantage of new capabilities.

We always endeavor to minimize our environmental impression and are creating a good manufacturing framework with focus on developing safe operations.

YOUR PARTNER IN CONTRACT MANUFACTURING

Technical and Manufacturing excellence is one of the core competencies of Excel Industries. We are open to manufacturing partnership and offer our services as a contract manufacturing partner for product innovator companies. Excel can leverage its assets and technology capabilities to be a cost effective partner in the space of Contract Manufacturing. Some of our key capabilities are listed below:

- Reaction volumes up to 2 million liters

- Filtration equipment ~ 30 of varying MOC

- Dryers & Flakers ~ 20 of varying MOC

- Distillation columns ~ 20 of varying heights and MOC

- Processing Temp range:-20 to 800°C

- Manufacturing sites: Roha, Lote & Visakhapatnam

- Waste water treatment: Captive treatment plant & Zero liquid discharge

- R&D: 30+ scientists

- Pilot facilities: Kilo lab to 100kgs range.

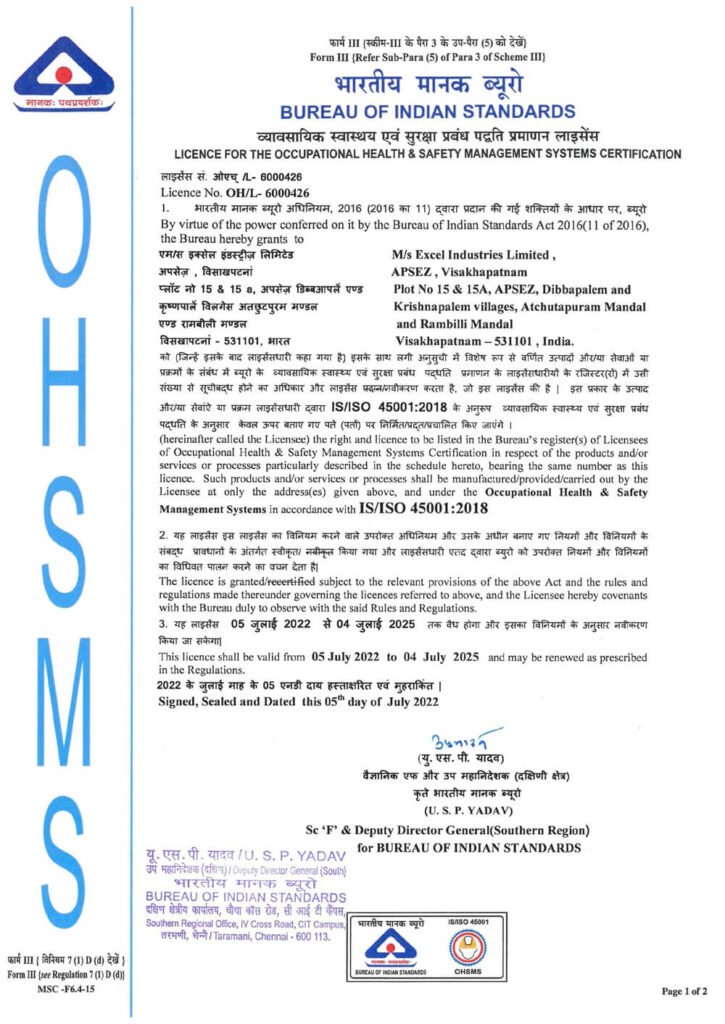

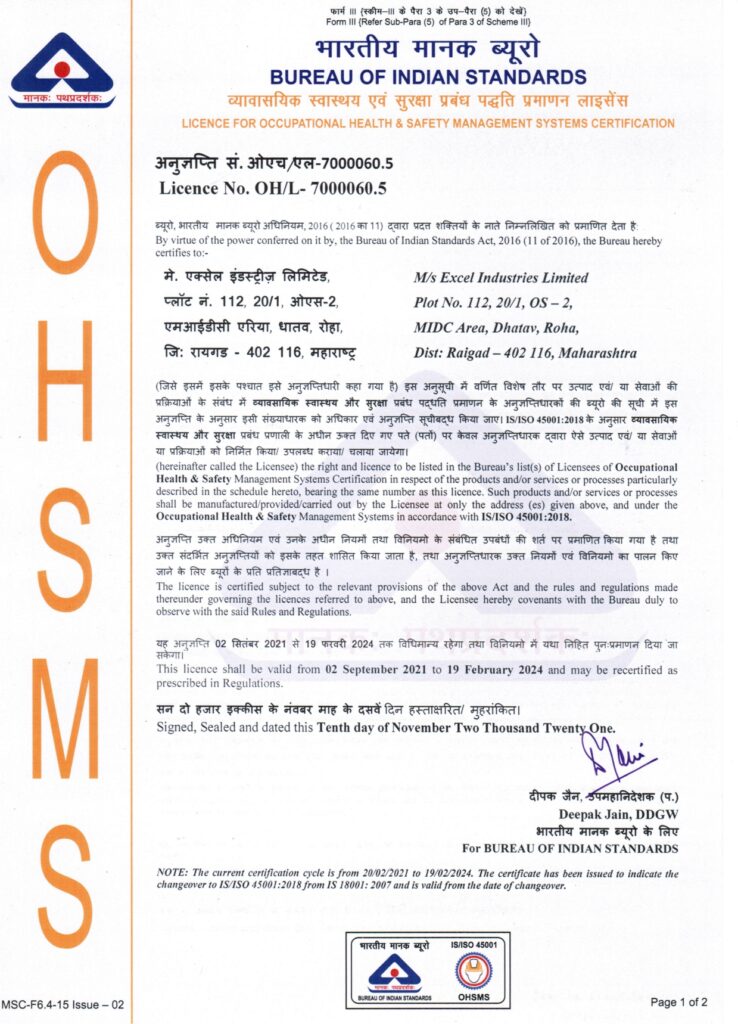

Good Health and Well Being

- Reduce Lost Time Injury Rate

- Motivated employees with good physical & emotional wellbeing.

- Improved labour relations leading to less disruptions

- Attract and retain quality employees.

Water and Pollution

- Reduce fresh water withdrawals.

Clean Energy

- Increase the share of Electricity from renewable energy

Decent work and Economic Growth

- Develop new products and applications.

- Fair work environment, on equity and core values.

Climate Actions

- Reduce absolute CO2 emissions

- Mitigate Climate change through tree plantations.